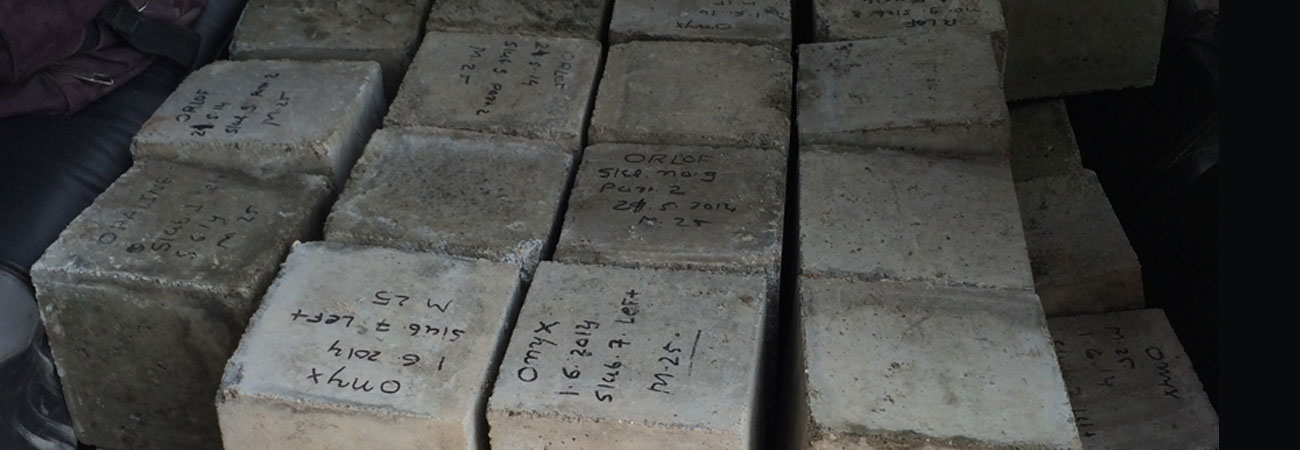

Non Destructive Testing Services

Non-destructive testing (NDT) refers to the testing/verification of materials, in order to check, inspect or evaluate the surface for the presence of any internal flaws, defects, and discontinuties,without damaging it or impairing its future usability. Basically, NDT testing is used to investigate the material integrity of the test item.

Importance of Non-destructive testing:

There are certain structures like huge machine (used in industries), massive pipelines, concrete structure, bridges and flyovers, prressure vessels, and many sophisticated machineries and structure, which because of their enormouse size and complexity have a certain natural risk factor associated with their current and future performance. The applications of this type of testing mainly apply to expensive items and structure.

Classification NDT technique can be categorized or classified into a number of types depending on the physical or chemical property utilized for the particular method. Some of the basic types are Visual, Liquid Penetrannt, Magnetic-particle, Radiography, Eddy Current testing, and Ultrasonic.

Conducting NDT test require an enhanced level of skill, experience and knowledge on the part of the operator, since the test results vary significantly with the expertise of the operator. Curve Surveys & Lab Ltd. has a team of extremely talented and diligent NDT inspectors, who are adequately trained and experienced in NDT testing/inspection of Structural and Building materials, both laboratory and on-site testing. We regularly provide NDT testing services to various industries like hydro-power, thermal power, fertilizers, petroleum refineries etc. We can also provide Residual Life Assessment and Structural safety tests for concrete bridges, water tanks and old buildings including those damaged by fire, as well as load test on bridge structures.